Introduction

Every year, crops across Africa and beyond are lost in storage. Not to insects, not to thieves, but to an invisible killer: the fungi Aspergillus. These fungi not only physically destroy the crops, but they also release highly dangerous aflatoxins, contaminating food and feed, causing cancer, stunting, and even death.

By the time Aspergillus are visible, it’s already too late. But what if we could detect the problem before we see it?

The Problem

Aspergillus thrive in hot, humid conditions, exactly the kind of environments where crops are stored in many parts of the world. Traditional testing methods like lab-based ELISA or LC-MS are accurate but slow, expensive, and out of reach for many storage room owners. As a result, contaminated crops are often detected only after they’ve entered the food chain.

The Innovation: A digital nose for Aspergillus detection

We’re building an AI-powered early warning system using volatile organic compound (VOC) sensors. These sensors detect subtle gas emissions from fungal growth as soon as they appear and before aflatoxins accumulate.

Think of it like a digital nose that constantly sniffs the air inside crop storage units. When it smells something wrong, it sends a real-time alert. The Bosch Sensortec sensor BME688 and accompanying software is a perfect, already on-the-market product to be implemented in our solution.

The sensor is tailored to only trigger a warning, if unique gases released by Aspergillus are “smelled”. This is possible because it communicates with an algorithm trained on Aspergillus-specific VOC’s, with the help of AI and machine learning.

Additionally, the sensors detect humidity and temperature, delivering real-time VOC-humidity-temperature data.

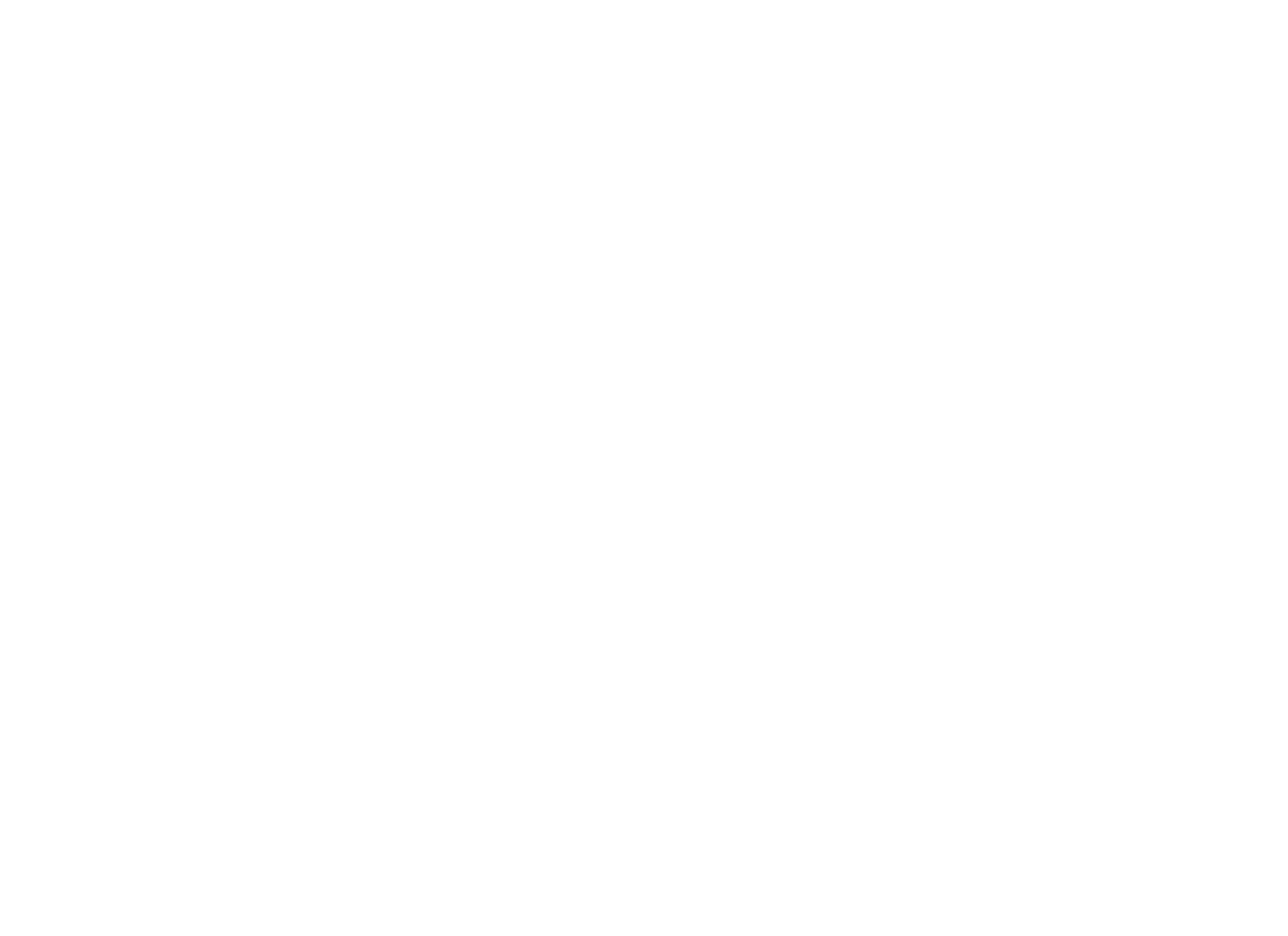

How It Works

- Aspergillus-specific algorithm is created. This only needs to be done once, but the algorithm can be improved as more data is collected.

- Sensor solution is installed in a warehouse. Each sensor unit contains the algorithm.

- Crops are stored in the warehouse.

- The sensors continuously monitor VOC, humidity and temperature levels.

- Data is constantly sent to a program in the cloud via WIFI or 3G.

- If gases are detected by the sensors, even at ppb levels, the program identifies a fungal risk.

- An alert is sent to a mobile phone, giving storage room owners time to act before aflatoxins accumulate.

Furthermore, if humidity or temperature levels are in the risk-zone for Aspergillus growth, the customer receives another warning to their phone.

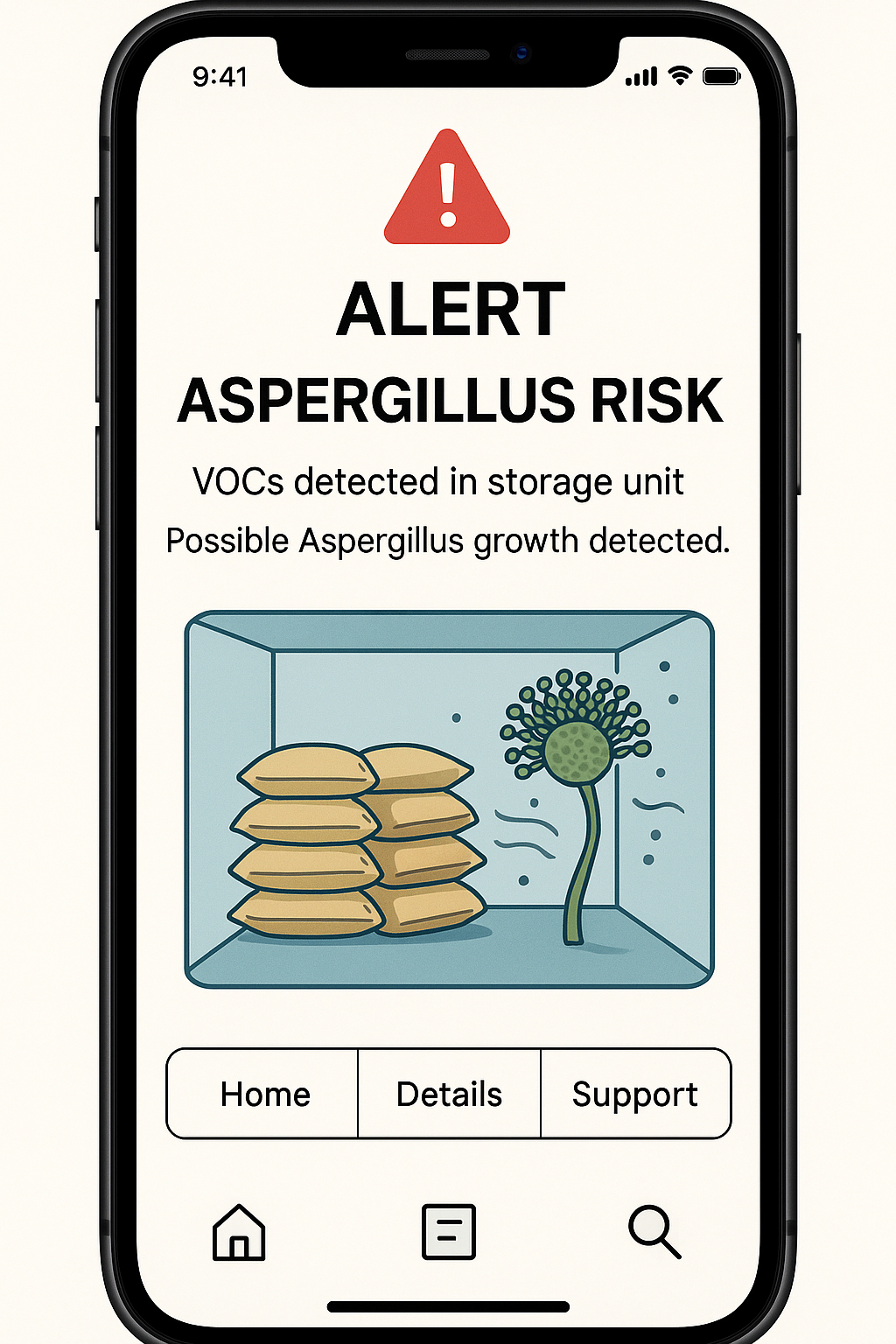

📱 Simple Alerts for All Users

Not everyone reads alerts. That’s why we’ve designed our system with voice messages, color-coded lights, and simple audio buzzers. Even if a user can’t read or isn’t tech-savvy, they’ll know exactly when and how to act:

- 🟢 Green = All good

- 🟡 Yellow = Risk detected

- 🔴 Red = Immediate action needed

Alerts are delivered to any mobile phone that has basic internet access functionality or even just standard SMS coverage and can receive notifications in our app or via SMS.

How It Works – Explained

The Algorithm

The software AI Studio by Bosch Sensortec is built to create algorithms based on sensor measurements. The BME688 and other Bosch sensors can record temperature, relative humidity, air pressure, and most importantly gas resistance. Gas resistance is what is measured when VOC’s are released from the source. The recording of gas resistance under specific conditions are fed to AI Studio, and the software will, based on machine learning, construct an algorithm that can tell the difference between specific scenarios in a room. This training is done under controlled conditions (in the lab). Let’s take the detection of Aspergillus feeding on maize as an example. First, the sensors are set to record the gas resistance in a room with only maize. The crop will naturally release its own specific set of VOC’s at certain concentrations. The sensor detects this as a gas resistance. Every 10.8 second, the sensor makes a new measurement. In fact, the sensor’s metal-oxide sensing layer, which is the component that reacts with VOC’s, changes temperature during each measurement, creating small variations in how it reacts with the gasses. This delivers a collection of gas resistances – a ‘fingerprint’ of the VOC composition – for one measurement. Repeating the cycle every 10.8 seconds gives a whole variety of fingerprints over time, each one recognized as maize and describing how its VOC’s vary. Now, this is only one run, with a specific set of room conditions. But change the conditions, and the VOC release from maize will also change. Several runs are performed, each with its own abundant set of fingerprints – all labelled ‘maize’. The exact same process is performed for Aspergillus and maize in the same room. Since the Aspergillus releases its own set of VOC’s, the fingerprints will vary from the fingerprints of maize without Aspergillus. The two separate enormous groups of fingerprints are fed to AI Studio, and an algorithm is built that knows the difference between the presence of Aspergillus on maize, and maize alone.

After an algorithm is built, it doesn’t need to be touched ever again – in theory. But as data is collected over time in real life application, patterns like Aspergillus risk and temperature will probably show. Remember that the sensor continuously records humidity, temperature and pressure. Additionally, we already know that Aspergillus releases different VOC’s depending on age and species. Thus, new training could improve the algorithm drastically, as more patterns are registered.

The Physical Setup

As a storage room owner buys our detection of Aspergillus, a number of strategically placed sensors are installed. The number depends on the size and infrastructure of the room. An advantage could be to divide the crops into sections. If Aspergillus is detected in one section, even without knowing the exact location, quick measures would be taken to handle that particular section. This would lessen the risk of spreading. If no sections are implemented, a denser grid of sensors might be necessary to exactly pinpoint how far the fungus has spread. A rough estimate is 16 sensors for a 100x50m area. The sensors capture raw data, the useful categories being gas resistance, temperature and humidity. Again, a measurement lasts for 10.8 seconds, changing the metal-oxide sensing layer’s temperature, just like during algorithm training, to not miss a recognizable set of gas resistances – a fingerprint. Though, the sensor itself can not tell if Aspergillus has been detected. It ‘only’ measures the gas resistances. Each sensor is connected to a microcontroller. The ESP32 microcontroller is an excellent option, since it is cheap, has WIFI and a low power consumption. The ESP32 on full usage has a yearly energy consumption of approximately 3.5 kWh, while the BME688 sensor uses around 0.114 kWh a year. This puts one set of ESP32 and sensor at 3.62 kWh a year, corresponding to 3 days of active use of a laptop. This is very little at industrial scale, and very cheap. Though, if for some reason the energy consumption is desired to be lower, the ESP32 can be set to upload data in batches, only turning on WIFI shortly every 5-10 minutes and storing data locally in the meantime. This saves about 50% of the power. The ESP32 is connected to ‘wall’ power. The sensor receives power from the microcontroller.

The ‘Invisible’ Setup

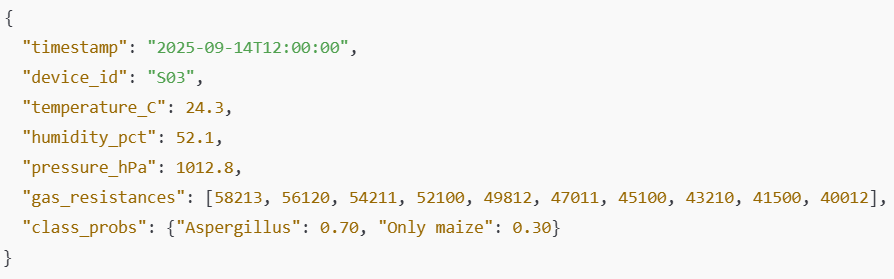

On the microcontroller, the Bosch Sensortec software BSEC is installed. BSEC contains the algorithm. The sensor essentially sends continuous raw data to the microcontroller. BSEC then converts the raw data into more useful data with the help of the algorithm. The most useful data output is a probability distribution between the contamination scenarios. In our example from before, this would be 1) Aspergillus plus maize and 2) maize alone. A single data output of this variable could be 1) 70% 2) 30%. This would mean the algorithm is recognizing the fingerprints of the presence of Aspergillus to a much higher degree than the presence of maize alone.

Raw data and processed data is sent via the microcontrollers WIFI to a database in the cloud that we own, for every sensor scan cycle (10.8 seconds). One single data package would look something like this:

Coupling this with location data, we have a comprehensive dataset for every storage room that has our solution installed. A program that we develop and own reads the new rows in the database as they come in. The program can be as complex as we want. It will to the very least detect trends and thresholds in relation to the contamination probabilities for each sensor and across sensors, based on the VOC measurements. It will also evaluate contamination risks based on temperature and humidity data. The same program will send a warning to the customers mobile phone, either via SMS, WhatsApp or to an app that we develop for this purpose. Email notification is also an option, though possibly not checked as often as a phone. If an app is developed, it gives us the ability to include resources for the customer, as well as easy access to more detailed, real-time information about the readings from their own warehouse. If not an app for the additional information, then a website could be an option. We think it would be a nice add-on for the customer to be able to track the monitoring of their storage room, if they are interested.

🧠 Summary

- The solution is powered by low-cost setup like the BME688 + ESP32.

- Most of the solution is digital and self-driven.

- The customer is not required to know anything about the technical aspect – a simple warning will appear on his/her mobile phone.

Why It Matters

This system is more than a gadget. It’s a game-changer for:

- Storage room owners and millers who want to protect their crops

- Traders who need clean crops for export

- Consumers who deserve safe, healthy food

- Governments trying to meet food safety standards

By shifting from reactive testing to proactive monitoring, we help stop the spread of Aspergillus, before aflatoxins accumulate and cause harm.

Impact & Vision

As we deploy these sensors across storage units and mills, we’re not just stopping aflatoxins and crop damage. We’re unlocking a new layer of ground-level agricultural data in regions where it’s never existed. As this solution expands, it will provide invaluable insights into climate trends, storage practices, Aspergillus growth conditions and crop health across Africa and beyond. The strongest potential is possibly that by coupling sensor data with location, the spread of Aspergillus can be live tracked locally, regionally and even nationally. All this data could drive innovation in Agri-Tech, supply chains, and food safety, fuelling smarter systems for farmers, governments, and tech companies alike.

Limitations

Our system has some important limitations to be aware of:

- Not direct aflatoxin measurement: The sensors detect VOCs and conditions linked to Aspergillus growth, not aflatoxin molecules themselves.

- Coverage needs: Very large warehouses may require many (50+) sensors for reliable detection. This would be investigated in pilot testing.

- Availability: Not all storage rooms might have WIFI for the microcontroller (which communicates with the VOC sensor) to connect to. This can be solved by storing the data on the microcontroller itself. A local alarm system is installed – this could be a sound alarm or LED light alarm. The microcontroller is then programmed to trigger the alarm, if there is a risk of Aspergillus. This solution would meet the basic goal – to inform the customer of an outbreak. For us to receive the data from the customer, it would require installation and then later collection of SD cards on and from the microcontroller, and manual upload to a database. Which is doable, since it would not be often (for example once every six months).

- Background grain odours: Large amounts of grain can release VOCs at much higher concentrations than Aspergillus, since the total mass of Aspergillus will be relatively very low compared to the mass of crop. This puts a possible limitation to the detection of Aspergillus – the sensor might just believe there is only the uncontaminated grain present at all times, because it gets overwhelmed by grain VOCs. Though, in the Bosch Sensortec solution, the gas resistances measured from the total presence of VOC are based on VOC mixtures, and not (only) concentrations. Aspgergillus’ unique VOC release contributes to a gas mixture that should make the AI based algorithm able to distinguish between healthy and unhealthy grain. It really comes down to how well the algorithm is trained and the conditions in the warehouse.

Despite these challenges, combining VOC data with humidity and temperature monitoring makes the system robust and practical for real-world use and accuracy will only improve as more training data is collected.

Considerations

Our system has some considerations to mention:

- Algorithm training challenges: In real-life scenarios, there are many variables and conditions for crop storage and Aspergillus growth. To utilize the Bosch Sensortec technology in our solution will require that we train an algorithm on a variety of scenarios. This includes environmental variability, amount of crop, Aspergillus age and Aspergillus species (the two dangerous being Flavus and Parasiticus). Though, Bosch AI Studio is built for this.

- Application broadness: Using the Bosch Sensortec technology, we have the choice between creating one algorithm, and therefore one solution, for every relevant type of grain, or one ‘master’ algorithm that covers multiple types of grain. This will have to be tested.

- Alternatives: Our solution asumes the use of Bosch Sensortec hardware and software and centers around this. But it is not the case that everything depends on this technology. In fact, our (to our knowledge) never thought of before idea is to utilize that Aspergillus releases its very own unique mixture of VOCs, to detect the presence of the fungi in storage rooms based on these gases. The innovation then arises with the use of the Bosch Sensortec VOC sensor and AI based software, which is potentially ideal for this application, but has never been used in this way before. Though, there exist alternative VOC sensors, and there is also the possibility to develop a new VOC sensor tailored for Aspergillus detection. Still, the setup presented today is what we believe is the most promising, and we are excited about the potential that this exact hardware and software can add to our whole solution.

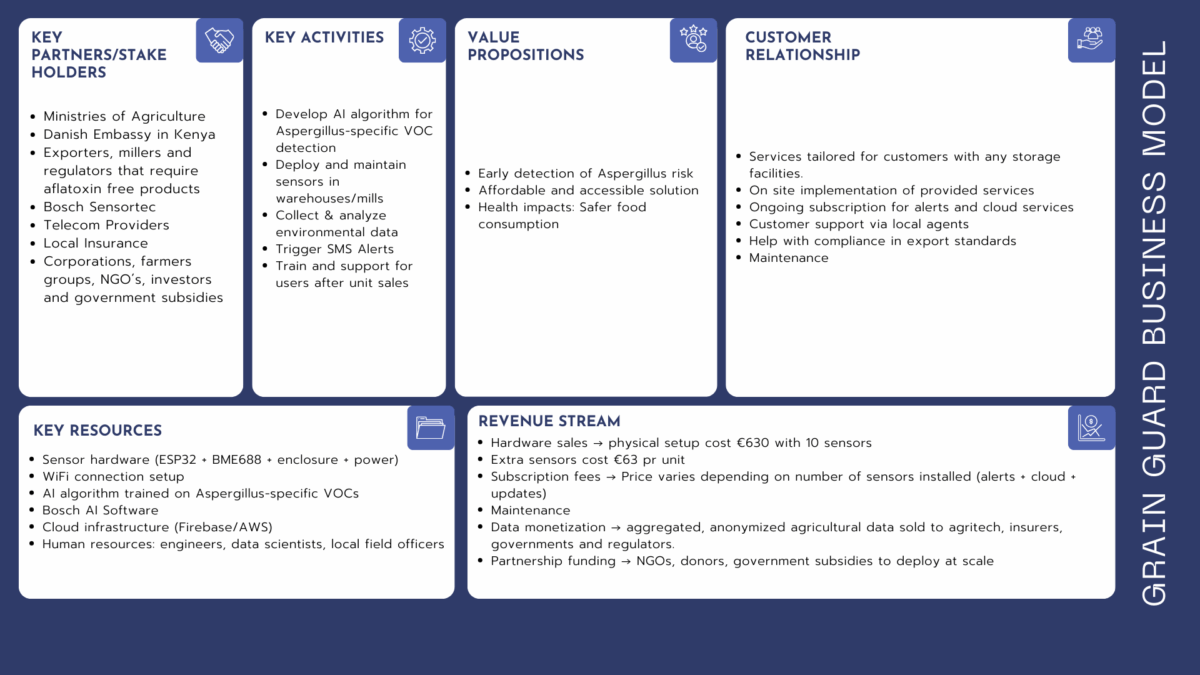

Business Model

Potential Savings

Lets assume that you are a storage unit owner and periodically discard your entire inventory due to aflatoxin growth. A simple setup of 10 sensors at the price of 630 € could potentially reduce the amount of crops being discarded or even prevent any crops from being discarded given the scenario that aspergillus is detected very early. That means the sensors quickly pay for themselves while saving you thousands of euros in preserved grain and protecting your business from devastating waste.

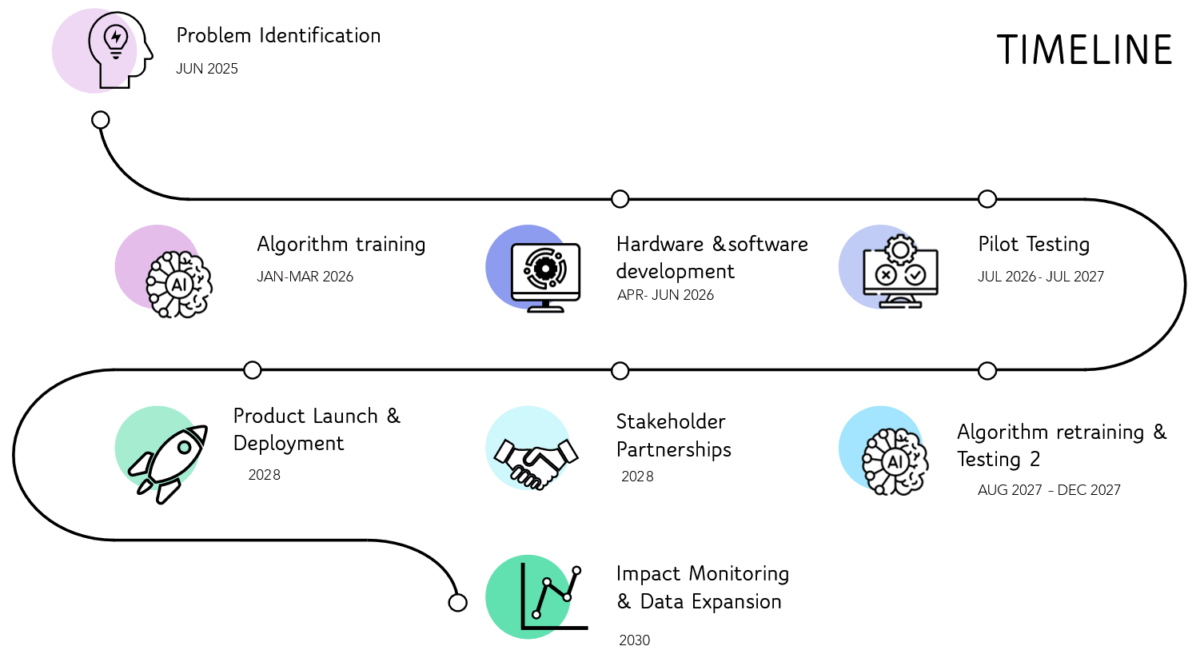

Timeline of the project

Let’s build a future where no family eats toxic crops, and no farmer loses their income to an invisible enemy.

Meet the Team