Smart Crops, Safe Crops: An Early Warning System for Aflatoxins

Introduction

Every year, crops all across Africa and beyond are lost in storage. Not to insects, not to thieves, but to an invisible killer: the fungi Aspergillus. These fungi not only physically destroy the crops, but they also release highly dangerous aflatoxins, contaminating food and feed, causing cancer, stunting, and even death.

By the time Aspergillus are visible, it’s already too late. But what if we could smell the problem before we see it?

The Problem

Aspergillus thrive in hot, humid conditions, exactly the kind of environments where crops are stored in many parts of the world. Traditional testing methods like lab-based ELISA or LC-MS are accurate but slow, expensive, and out of reach for many storage room owners. As a result, contaminated crops are often detected only after they’ve entered the food chain.

The Innovation: A digital nose for Aspergillus detection

We’re building an AI-powered early warning system using volatile organic compound (VOC) sensors. These sensors detect subtle gas emissions from fungal growth as soon as they appear and before aflatoxins accumulate.

Think of it like a digital nose that constantly sniffs the air inside crop storage units. When it smells something wrong such as Epizonaren, 2-Methylpropan-1-ol, 2-Methylbutanal or other spoilage gases, it sends a real-time alert.

The “nose” is tailored to only trigger a warning, if unique gases released by Aspergillus are “smelled”. This is possible because it contains an algorithm trained on Aspergillus-specific VOC’s, with the help of AI and machine learning.

Additionally, the sensors detect humidity and temperature, delivering real-time VOC-humidity-temperature data.

How it Works

- Aspergillus-specific algorithm is created. This only needs to be done once.

- Sensors are installed in a warehouse. They contain the algorithm.

- Crops are stored in the warehouse.

- The sensors continuously monitor VOC, humidity and temperature levels.

- Data is constantly sent to a program in the cloud via WIFI or 3G.

- If gases are detected by the sensors, even at ppb levels, the program identifies a fungal risk.

- An alert is triggered, giving storage room owners time to act before aflatoxins accumulate.

Furthermore, if humidity or temperature levels are in the risk-zone for Aspergillus growth, the customer receives another warning.

📱 Simple Alerts for All Users

Not everyone reads alerts. That’s why we’ve designed our system with voice messages, color-coded lights, and simple audio buzzers. Even if a user can’t read or isn’t tech-savvy, they’ll know exactly when and how to act:

- 🟢 Green = All good

- 🟡 Yellow = Check storage

- 🔴 Red = Immediate action needed

Alerts are delivered via any mobile phone that has basic internet access functionality or even just standard SMS coverage and can receive notifications in apps or SMS.

🧠 Smart + Affordable

- Powered by low-cost sensors like the BME688, which detects fungal VOCs, humidity and temperature.

- Most of the solution is digital and self-driven.

- The customer is not required to know anything about the technical aspect – a simple warning will appear on his/her mobile phone.

Why it Matters

This system is more than a gadget. It’s a game-changer for:

- Storage room owners and millers who want to protect their crops

- Traders who need clean crops for export

- Consumers who deserve safe, healthy food

- Governments trying to meet food safety standards

By shifting from reactive testing to proactive monitoring, we help stop aflatoxins before they cause harm.

Impact & Vision

As we deploy these sensors across storage units and mills, we’re not just stopping aflatoxins and crop damage, we’re unlocking a new layer of ground-level agricultural data in regions where it’s never existed. As this solution expands, it will provide invaluable insights into climate trends, storage practices, and crop health across Africa and beyond. The strongest potential is possibly that by coupling sensor data with location, the spread of Aspergillus can be live tracked locally, regionally and even nationally. All this data could drive innovation in Agri-Tech, supply chains, and food safety, fuelling smarter systems for farmers, governments, and tech companies alike.

Call to Action

We’re looking for:

- Partners in agriculture, public health, and policy

- Investors who care about food safety innovation

- Farmers’ groups and cooperatives ready to pilot the system

Let’s build a future where no family eats toxic crops, and no farmer loses their income to an invisible enemy.

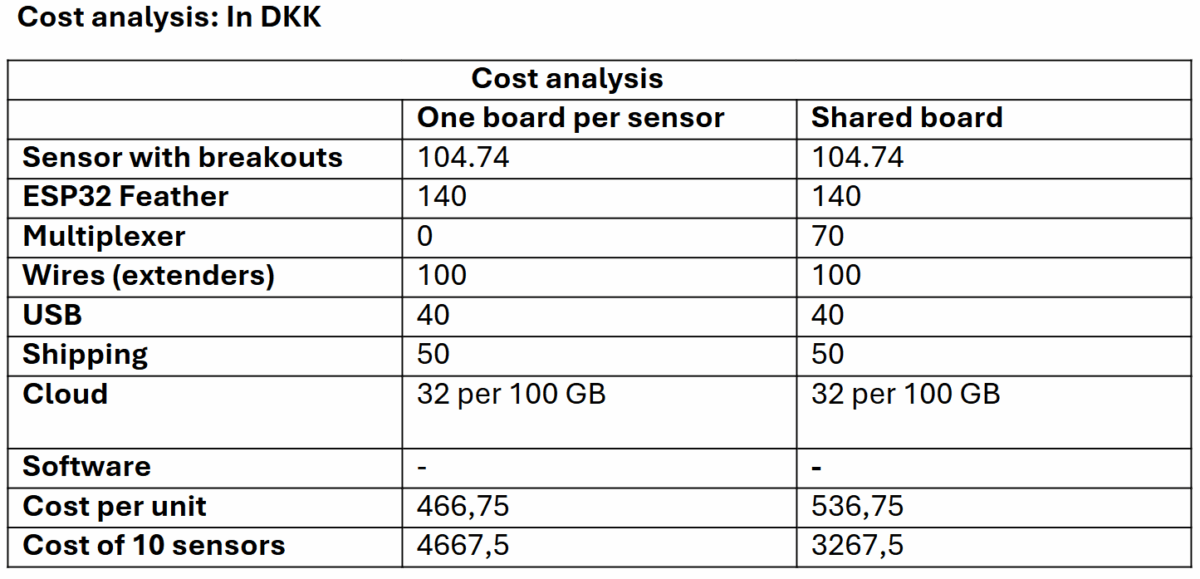

Cost Analysis

Example of setup in storage room

This is an illustration of how the setup could be in the storage room. In this example, four sensors are connected to one single ESP32 board. It is the ESP32 board which sends the data collected by the sensors to the cloud. A multiplexer is needed to connect several sensors to one ESP32 board. Another scenario is that each sensor is connected to its own ESP32 board. This would reduce the amount of wires needed but improve the overall cost since more ESP32 boards would be required.