INTRODUCTION

Aflatoxins are highly toxic secondary metabolites produced by Aspergillus flavus and A. parasiticus, fungi that frequently contaminate staple crops like maize and groundnuts. In Kenya, aflatoxin outbreaks have had severe health and economic repercussions, especially in rural areas where maize is a dietary staple and post-harvest handling practices are often inadequate (Wanjiru et al., 2023; Mahato et al., 2019). Detecting and managing aflatoxin contamination is therefore critical for food safety, public health, and trade integrity (Sirma et al., 2018).

OVERVIEW OF AFLATOXIN

Aflatoxin B1 is the most potent and widespread, classified as a Group 1 carcinogen (carcinogenic to humans) by the International Agency for Research on Cancer (IARC). Exposure can lead to severe health issues, including liver cancer, immunosuppression, and childhood stunting. Kenya has experienced devastating outbreaks of acute aflatoxicosis, most notably in 1985 and 2004, which resulted in numerous hospitalizations and fatalities. The 2004 outbreak alone led to 312 hospitalizations and 125 deaths.

Current ways to Perceive Aflatoxin

Hyperspectral Imaging

- Hyperspectral imaging techniques, including reflectance, fluorescence, and Raman imaging, have shown high accuracy in detecting aflatoxins in maize. For instance, fluorescence and short-wave infrared (SWIR) imaging achieved classification accuracies of 95.7% with no false negatives at a 10 μg/kg cutoff, making them promising tools for rapid screening (Rashid et al., 2022).

- SWIR hyperspectral imaging has been used to detect aflatoxin B1 in individual maize kernels, employing principal component analysis and support vector machine classification to effectively identify contamination levels (Long et al., 2022).

Fluorescence Spectroscopy

- Fluorescence spectroscopy, both one- and two-photon induced, offers a non-destructive method for detecting aflatoxins. This technique exploits the intrinsic fluorescence differences between contaminated and uncontaminated maize, providing a basis for real-time industrial scanning (Kim et al., 2010).

- A handheld fluorescence spectrometer has been developed, demonstrating high sensitivity in detecting aflatoxins in maize, with potential for integration along the food chain to improve food safety (Smeesters et al., 2023).

Defining The Problem

Despite Kenya having set national aflatoxin standards, contamination levels in cereals and feeds often exceed safe limits (Wanjiru et al., 2023). Manual and laboratory-based testing methods are costly, slow, and inaccessible for most smallholder farmers. This leads to unchecked exposure and significant health burdens, including hepatocellular carcinoma and stunted growth in children (Kumar et al., 2021; Mahato et al., 2019).

The problem of aflatoxin in Kenya is multifaceted, affecting public health, food security, and the economy. Key issues include the frequent entry of contaminated maize into the food supply, leading to acute aflatoxicosis outbreaks, erosion of market trust, and significant economic losses for farmers due to rejected produce and trade disruptions. This situation creates a trade-off between food safety and food security, making regulation difficult.

Research Questions

- How can emerging digital technologies improve the early detection of aflatoxins in Kenyan crops?

- What role can weather data and remote sensing play in predicting aflatoxin risk zones?

- Which digital tools offer the most cost-effective, scalable solutions for aflatoxin monitoring in rural Kenya?

Objectives

- To identify suitable digital technologies for aflatoxin detection.

- To assess the feasibility of integrating weather data for aflatoxin risk prediction.

- To engage stakeholders in evaluating digital tools for adoption and to analyze the cost-benefit ratio of digital versus conventional methods.

Justification

Kenya faces a persistent challenge of aflatoxin contamination due to its tropical climate, poor post-harvest practices, and limited access to effective detection tools (Sirma et al., 2018). Emerging digital technologies such as hyperspectral imaging, machine learning, and mobile diagnostics provide promising, scalable alternatives to traditional methods. These innovations can enable early warning systems, improve response times, and reduce health risks (Mahato et al., 2019; Kumar et al., 2021).

Summary of Research & Literature Review

Traditional aflatoxin detection methods like ELISA, HPLC, and TLC are precise but require lab infrastructure, technical skills, and time (Mahato et al., 2019; Kumar et al., 2021). Recent advancements offer rapid, field-deployable techniques.

Mode of Occurence of Aflatoxin

Maize Storage System

Aflatoxin contamination is exacerbated by poor storage practices. The main maize storage systems in Kenya can be categorized as follows:

- Farm Storage: Stooking, where maize is piled in the field to dry, is a common practice.

- Home Storage: Maize is stored in sisal sacks, often in sealed, dark rooms.

- National Reserve Granaries: Large-scale commercial storage facilities are used for national food reserves.

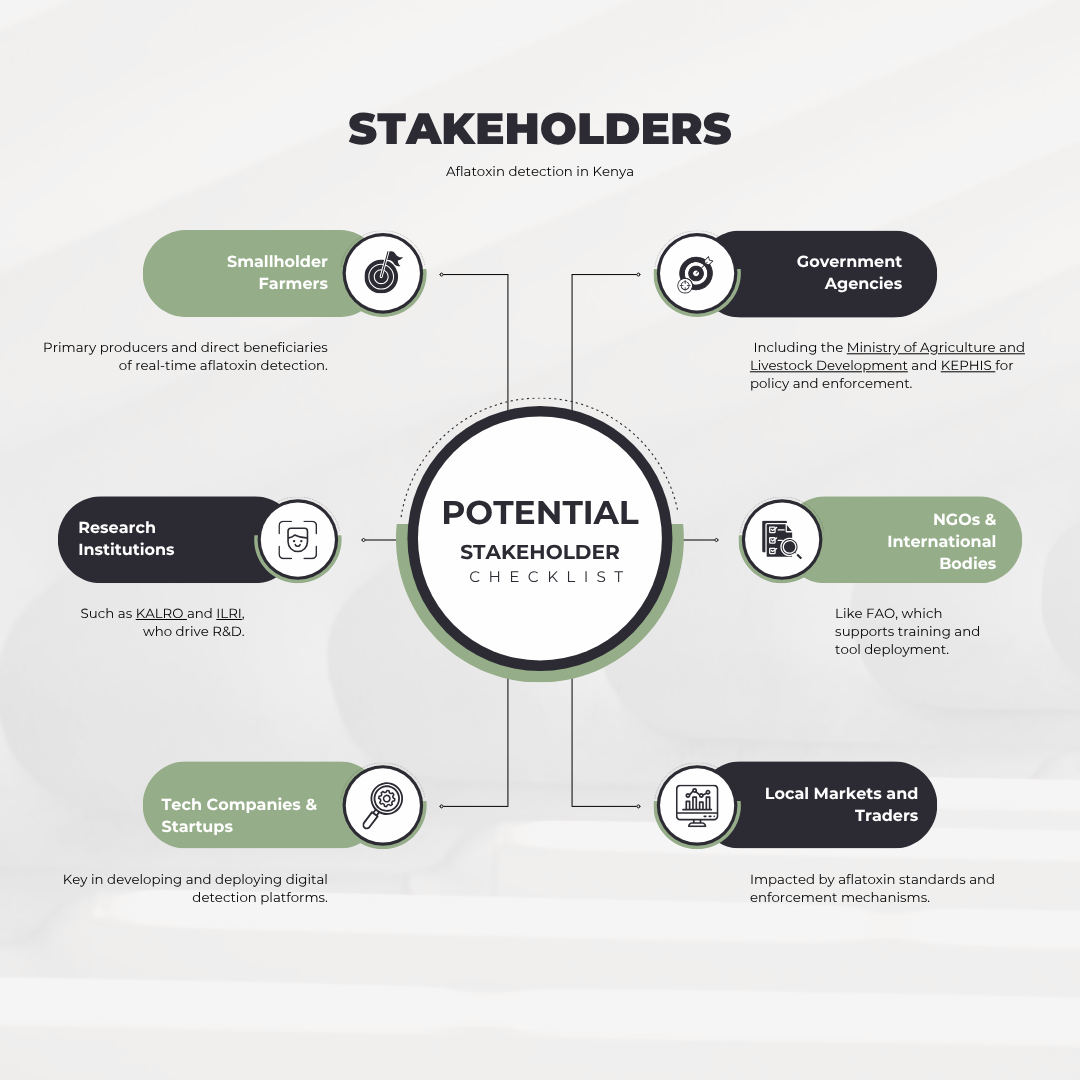

Stakeholders

Addressing the aflatoxin problem requires a collaborative effort from various stakeholders across the value chain. The key players include:

- Government Agencies: Responsible for policy development, regulation, and enforcement.

- Tech Companies: Developers of innovative solutions for detection and management.

- NGOs and International Organizations: Provide research, awareness, and funding.

- Research Institutions: Conduct scientific research and develop new mitigation strategies.

- Local Markets and Traders: The points where contaminated produce often enters the food supply.

- Smallholder Farms: The primary producers who are most vulnerable to crop loss and economic hardship.

Solution Approach: Integrating Weather Data

Weather conditions significantly influence aflatoxin outbreaks. Temperature, humidity, and rainfall during pre- and post-harvest stages determine fungal growth and toxin production (Mahato et al., 2019; Kumar et al., 2021). Integrating weather data allows:

- Satellite Remote Sensing: To monitor real-time climatic changes.

- Agro-meteorological Forecasts: To predict high-risk aflatoxin seasons.

- Mobile-based Alert Systems: To inform farmers when to harvest, dry, or store crops.

- AI-powered Decision Support Systems: To advise on mitigation strategies based on weather-driven risk maps.

This predictive framework can minimize contamination before it occurs, improving food safety and reducing economic losses (Mahato et al., 2019).

Unmasking the Challenge to Propose Solution

Current aflatoxin detection and management methods are often ineffective or inaccessible to smallholder farmers and traders. The primary challenges include:

- Late Detection: Contamination is often only identified after the produce has entered the market or caused illness.

- Inaccurate Prediction: Traditional methods do not effectively predict outbreaks.

- Inaccessible Data: Data on contamination hotspots and risk factors are not readily available to those who need it.

- High Costs: Conventional laboratory methods like High-Performance Liquid Chromatography (HPLC) and Enzyme-Linked Immunosorbent Assay (ELISA) are expensive and require specialized equipment.

VALUE CHAIN ANALYSIS

Aflatoxin contamination occurs at every stage of the maize value chain. From pre-planting to post-harvest handling and storage, the risk of fungal growth and toxin production is ever-present. The economic impact is profound, with significant losses due to reduced yields, health care costs, and rejected exports. For smallholder farmers, this can result in a gross value loss of approximately $4,580 and an aflatoxin-related loss of about $114 per hectare.

Our Product

PROPOSAL

The ADDiCT proposal is to leverage emerging digital technologies to create a comprehensive and accessible aflatoxin detection system. This technology will provide real-time monitoring and predictive analysis at various stages of the agricultural value chain pre-planting, pre-harvest, and post-harvest to empower farmers and stakeholders to make informed decisions. The core components of the proposal include the use of Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT).

HOW OUR PRODUCT WORKS

ADDiCT utilizes a multi-sensor approach to detect aflatoxin contamination. A key component is a drone equipped with UV spectral and hyperspectral sensors. Drone flies over maize fields to detect characteristic fluorescence of Aflatoxins on plant parts before the flowering stage and maize development of the plant. Additionally, the system includes stationary sensors that can be placed in storage rooms or on trucks to monitor moisture, temperature, and other conditions conducive to fungal growth. The Size (dimensions) of the drone is 30-60cm with a Flight time of over 45 minutes with Payload size of low to medium (5kg) and a Battery type of 20000 mah Silicon Carbide battery (More capacity in a small factor). The Battery charging speeds is above 60W (Fast Charging) and distance per flight is 6km. The speed of the drone is 8km/h. This slow pace is recommended for absolute scanning of fields

HOW THE DATA WORKS

The ADDiCT system is entirely data-driven, using predictive analytics to provide actionable insights. The sensors on the drone and in the stationary units collect data on environmental conditions and spectral signatures. This data is then transmitted via a communication chip to a central system where AI and ML algorithms analyze the information to predict the likelihood and severity of contamination. This allows for the creation of early warning systems and targeted interventions.

PRODUCT IMPACT

The ADDiCT system aligns with several Sustainable Development Goals (SDGs) and offers significant benefits to various stakeholders.

- SDG 1: Protects smallholder farmers from income losses caused by contaminated crops, reducing poverty risks

- SDG 2: Zero Hunger: It improves food security by reducing pre- and post-harvest losses caused by contamination.

- SDG 3: Good Health & Well-being: By providing early detection, the system lowers the risk of aflatoxin-related health issues such as liver cancer, stunting, and immune suppression.

- SDG 8: Decent Work & Economic Growth: The technology increases farmer income and provides better access to premium markets by ensuring the quality of their produce.

- SDG 12: Responsible Consumption & Production – Ensures safer, sustainable food supply chains.

- SDG 17: Partnerships for the Goals: The system fosters collaboration among farmers, governments, researchers, and other organizations to create a unified approach to food safety.

Business Model & Revenue Stream

The ADDiCT project’s core business model is a hybrid approach designed to serve the diverse needs of its key stakeholders, from smallholder farmers to large commercial enterprises. This model prioritizes social impact by making technology accessible while ensuring financial sustainability for all involved parties.

It is structured as a “Profit for Purpose” model, where the primary goal is not just to maximize profits, but to use technology to solve a critical social problem of aflatoxin contamination. This approach aligns with the project’s mission of improving public health and economic well-being across the agricultural value chain.

The primary revenue streams are segmented to provide value and monetize the service effectively:

- Subscription-Based Model: For larger stakeholders like commercial farms, food processing companies, and government agencies, a monthly or annual subscription fee provides continuous access to the full suite of ADDiCT services. This includes:

- Proactive Monitoring: Regular, scheduled drone and sensor-based field analysis for early detection of contamination risks.

- Predictive Analytics: Access to a central data dashboard with advanced analytics and predictive models to forecast potential outbreaks and identify high-risk areas.

- Data API: Integration with the client’s existing supply chain and management software for real-time data exchange.

- This predictable revenue stream allows the company to invest in research and development, scale its operations, and maintain a high level of service.

- Hiring/Pay-Per-Service for Smallholder Farmers: The high cost of equipment makes ownership impractical for smallholder farmers. To address this, ADDiCT will operate a “drone-as-a-service” model.

- How it Works: Farmers, either individually or through cooperatives, can hire a certified ADDiCT service provider to conduct a one-time scan of their farm. The cost would be based on the acreage or a per-service fee, making it an affordable, on-demand solution.

- Benefits: This model provides smallholders with access to cutting-edge technology without any upfront capital investment, empowering them to detect aflatoxin, reduce crop losses, and command higher prices for their produce. It is a win-win: farmers increase their income, and the ADDiCT project generates revenue from a large and critical market segment.

- Buying and Ownership: For research institutions, universities, and large-scale agribusinesses, the outright purchase of the ADDiCT technology suite including the drones, mobile lab equipment, and a software license is an option. This model caters to clients who require full control and integration of the technology for extensive research or internal operations.

- How Tech Companies Will Make Money: The combined revenue streams of subscriptions, pay-per-use services, and outright sales form a robust financial model. Beyond direct service provision, the company will generate additional income from high-value activities:

- Data Monetization: Anonymized and aggregated data from all users can be analyzed and sold as market insights to agricultural policymakers, financial institutions (for risk assessment), and food traders. This data provides invaluable information on crop health, regional trends, and harvest projections.

- Consulting Services: Offering specialized consulting to government bodies and NGOs on aflatoxin mitigation strategies, based on the vast data and expertise accumulated by the platform.

- Partnerships and Integration Fees: Partnering with seed companies, fertilizer suppliers, and agricultural financial lenders, charging them fees to integrate their services into the ADDiCT platform. This creates a powerful ecosystem that benefits all actors in the agricultural value chain.

IMPLEMENTATION PLAN

The implementation of ADDiCT will follow a phased approach, focusing on key stages of the maize value chain.

- Phase 1: Pre-planting: The initial phase will focus on using the system’s predictive analytics to identify high-risk areas based on historical data, soil sample and climate forecasts. This will allow farmers to make informed decisions on crop selection and planting times.

- Phase 2: Pre-harvest: The drone-based detection system will be deployed to scan fields and identify early signs of fungal growth, enabling timely intervention to prevent widespread contamination.

- Phase 3: Post-harvest: Stationary sensors will be installed in farm and commercial storage facilities to monitor conditions and alert farmers to potential contamination risks, helping them to preserve the quality of their harvest.

FUTURE OPPORTUNITIES

The ADDiCT technology offers numerous opportunities for future development and expansion.

- Scaling the Technology: The system can be scaled to cover more regions in Kenya and eventually other parts of Africa, where aflatoxin contamination is a major issue.

- Expanded Crop Application: The technology can be adapted to detect aflatoxin in other susceptible crops like groundnuts, sorghum, and millet.

- Advanced Predictive Models: Continuous data collection will allow for the development of more accurate and sophisticated predictive models, providing even earlier warnings and more effective management strategies.

- Public-Private Partnerships: There is significant potential for partnerships with government bodies, research institutions, and the private sector to further research and development and ensure widespread adoption of the technology.

References

- Awuor, A. D., Sirma, J. D., & Mutegi, C. (2022). Farmer awareness and management of aflatoxins in groundnuts in western Kenya. Zenodo.

- Mutegi, C., & Wanjiru, S. (2018). Prevalence and mitigation of aflatoxins in Kenya (1960-to date). BMC Research Notes, 11(1), 844.

- Sirma, J. D., Ouko, D., & Muturi, P. (2018). Management strategies for aflatoxin risk mitigation in maize, dairy feeds and milk value chains—case study Kenya. Food Quality and Safety, 2(4), 213–220.

- Strosnider, H. M., et al. (2006). Workgroup report: public health strategies for reducing aflatoxin exposure in developing countries. Environmental Health Perspectives, 114(12), 1898–1903.

- Wanjiru, S. W., et al. (2023). Risk mitigation of aflatoxin contamination in maize and its food and feed products in developing countries: a review. East African Journal of Science, Technology and Innovation, 4(1), 1-15.

TEAM MEMBERS